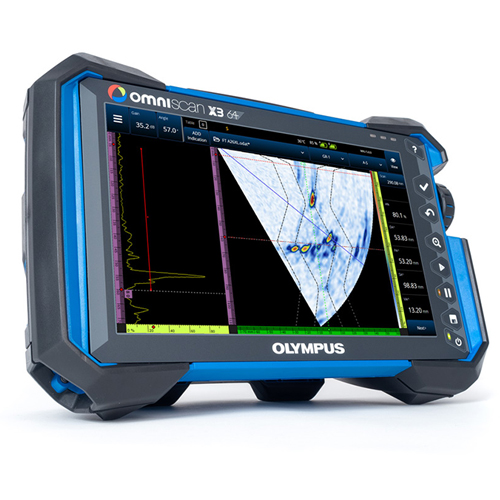

OmniScan X3 64 flaw detector delivers improved power and performance to Olympus field-proven phased array ultrasonic testing (PAUT) product line.

This 64-channel instrument has the pulser capacity to drive phased array (PA) probes with a larger number of elements, increasing the data acquisition speed for total focusing method (TFM) imaging. Users can exploit its increased capabilities to expand and diversify their application portfolio.

The Olympus OmniScan X3 64 Phased Array Flaw Detector was introduced and released by Olympus Corporation in February 2202. The OmniScan X3 flaw detector has the tools to help you complete your work efficiently. Its range of applications include welds, pipelines, pipes, corrosion-resistant alloys, corrosion mapping, HTHA inspection, detection of stepwise cracking, composite inspection, and flaw imaging.

- Compatible with existing probes and scanners

- 32:128PR model, featuring 64-element TFM

- 16:64PR and 16:128PR also available

- Up to 8 groups, 1,024 focal laws

- Compatible with MX2/SX files for convenience

- 64 GB internal storage, extendable with an external USB drive

Features:

- Powerful software that’s intuitive for new and existing OmniScan users with a modern, simplified menu structure that minimizes button presses.

- Live TFM Envelope Processing. The instrument’s unique envelope processing provides clear, high-resolution TFM images of flaws.

- Facilitate Flaw Interpretation and Sizing. Using different TFM modes (wave sets) in the same inspection provides more chances to detect oddly oriented indications.

- Confirm Your Coverage in Advance. The acoustic influence map (AIM) tool provides you with an instant visual model of the sensitivity based on your TFM mode, probe, settings, and simulated reflector.

- Get to Work, Quickly. The onboard scan plan tool helps you visualize your inspection before you begin.

- Improved Fast Calibration. The OmniScan X3 calibration menus track the signals at high speed. You can perform multiple group calibrations in minutes with minimal frustration

- Harness the Power of Your PC. OmniPC™ software offers a suite of advanced tools, such as a side-by-side view that enables you to compare two files onscreen at the same time to maximize the power of your PC when analyzing data.

Applications:

- In-service and construction welding

- Pressure vessels

- Process pipes

- Wind tower

- Structural construction

- Corrosion-resistant alloys and cladded materials (austenitic, nickel, and other coarse-grained materials)

Power You Can Carry

The high portability and enhanced performance of the OmniScan X3 64 flaw detector increase inspection productivity. It can process TFM images up to four times as fast as its predecessor yet comes in the same rugged and easily transportable box. On job sites with limited or restricted space, users will appreciate that the OmniScan X3 64 unit is compact and less cumbersome than other 64-channel devices. Inspectors can also remain on site longer and perform bigger scanning jobs without transferring data, thanks to the large 1 TB onboard storage.

Ease Challenging and Advanced Applications

Facilitating complex and thick part or weld applications, the instrument’s full 64-element aperture PA and 128-element aperture TFM enables users to optimize advanced Dual Linear Array (DLA) and Dual Matrix Array (DMA) probes. To save time during setup, all models in the OmniScan X3 series have integrated DLA and DMA support.

Smaller defects are easier to distinguish using the OmniScan X3 64 flaw detector’s high-resolution PA and TFM imaging. Accommodating lower frequency probes, the OmniScan X3 64 unit can increase penetration in attenuative materials while reducing signal saturation. These improved detection capabilities assist monitoring for early-stage flaws, such as high-temperature hydrogen attack (HTHA).

Optimized Workflow for Large Parts

When applications require advanced analysis, the entire PA inspection workflow can be performed using Olympus’ WeldSight software for greater efficiency. With the WeldSight Remote Connect app installed on the OmniScan X3 64 unit, users can instantly view the acquired data on a PC, exploiting the customizable user interface and software tools that facilitate specialized inspection procedures, including new-fabrication welds in pressure vessels

Specifications:

Storage Devices: Storage Devices: SDHC™ and SDXC™ cards or most standard USB storage devices

Hard Drive Capacity: Hard Drive Capacity: Internal 64 GB SSD, extendable using an external USB drive

GPS: Yes (unless specified otherwise for some regions)

Wireless Connection: Wireless Connection: Yes (USB dongle sold separately as an accessory)

Lithium-ion Battery: Lithium-ion battery: 5 hours using 2 batteries (hot-swap capable)

Number of Receiving Elements: Number of Receiving Elements: OMNIX3-PATFM32128PR = 128 receiving elements

Ingress Protection Rating: Ingress Protection Rating: IP65 certified (completely protected against dust and water jets from all directions (6.3 mm nozzle)

Operating Temperature: Operating Temperature: 0 °C to 45 °C (32 °F to 113 °F)

Storage Temperature: Storage Temperature: −20 °C to 60 °C (−4 °F to 140 °F) (with battery inside) −20 °C to 70 °C (−4 °F to 158 °F) (with no battery inside)

Weight: 5.7 kg (12.6 lb) (with 1 battery)

Dimensions: (W × H × D): 335 mm x 221 mm x 151 mm (13.2 in. x 8.7 in. x 5.9 in.)

Package includes:

- OmniScan X3 64 flaw detector 16:64PR

- OmniScan MXU software

- 10L16-9.6X10-A10-P-2.5-OM: Standard Phased Array Probe, 10 MHz Linear Array, 16 Elements

- SA10-IHC: Standard removable IHC option for SA10 wedges

- SA10-N55S: Standard wedge for angle beam phased-array probe A10

- SA10-N55S-AOD3.5: Standard wedge for angle beam phased-array probe A10

- SA10-N55S-AOD4.5: Standard wedge for angle beam phased-array probe A10

- SA10-N55S-AOD6.625: Standard wedge for angle beam phased-array probe A10

- SA10-N55S-AOD8.625: Standard wedge for angle beam phased-array probe A10

- SA10-N55S-AOD10.750: Standard wedge for angle beam phased-array probe A10

- SA10-N55S-AOD12.750: Standard wedge for angle beam phased-array probe A10

- SA10-N55S-AOD24: Custom Wedge for Angle Beam Phased-Array Probe A10

- 5L32-32X10-A32-P-5-OM: Standard Phased Array Probe, 5.0 MHz Linear Array, 32 Elements

- SA32-N55S-IHC: Standard Wedge for Angle Beam Phased-Array Probe Type A31

- ENC1-5-LM: Mini encoder, 5 m cable, waterproof with Lemo connector

- WTR-SPRAYER-8L: Portable manual couplant feed unit

- TB7567-1: NAVSHIPS Block. 1018 Steel

- 93 Wh lithium-ion battery

- Spare screen protector

- DC charger with power cord

- USB key with MXU Software and User’s Manuals

- Empty USB key for file transfer purposes

- Complimentary OmniPC analysis software

- Calibration certificate

- Transport case

Resources: Olympus-OmniScan-X3-64-Brochure