Olympus OmniScan MX 16:128 ECA/ECT PA Flaw Detector is a portable, versatile NDT (Nondestructive Testing) instrument designed for advanced flaw detection using both Phased Array Ultrasonic Testing (PAUT) and Eddy Current Array (ECA) or Eddy Current Testing (ECT) technologies.

This model is part of the OmniScan MX platform, known for modular, field-ready flaw detectors capable of performing inspections across various industries, including aerospace, oil & gas, and manufacturing.

Olympus OmniScan MX

Olympus OmniScan MX With thousands of units being used throughout the world, the OmniScan® MX is a field-proven, reliable instrument that is built to withstand harsh and demanding inspection conditions. Compact and lightweight, its two Li-ion batteries

Olympus OmniScan MXThe highly legible 8.4 in. (213 mm) real-time color display of the

MX enables you to see defects and details under any light conditions. Navigate your way through the instrument’s simple and intuitive interface using the scroll knob and function keys, or by connecting a USB mouse to facilitate the inspection analysis.

One Platform, Two Modules, Three Technologies: More Flexibility

To meet the requirements of a broader range of applications, eddy current testing (ECT), eddy current array (ECA) and the new bond testing (BT) C-scan technology are available in two module versions. Both of these modules are compatible with the MXE (ECT/ECA) and MXB (BT C-scan) software, providing easy transition between technologies and a very short learning curve.

Olympus OmniScan MX

Conventional ECT

Eddy Current Array

Bond Testing C-Scan

|  |  | |

| |||

| ECT4 module | √ | Not supported | √ |

| ECA4-32 module | √ | √ | √ |

| Most Nortec probes supported | Supports 32 onboard channels and 64 channels with external multiplexer | Requires special adaptor and scanner |

ECA is just like ECT

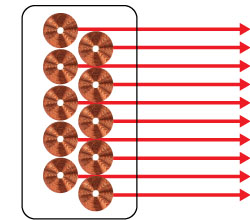

Large Coverage, Fast Scanning, and Higher Probability of Detection

Eddy current array (ECA) technology incorporates several traditional bridge or reflection (driver-pickup) probe coils in order to achieve a much larger coverage in a single inspection pass. Additionally, each ECA probe model is carefully designed to maintain a high probability of detection of a targeted defect range, all along the probe length. With the OmniScan® MX ECA, you can use ECA probes at fast manual-inspection speeds, offering a powerful and productive inspection with color representation and archiving capability.

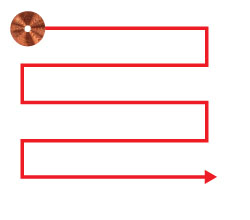

Single coil: raster scanning |  Array probe: one-line scanning |

Inspection through Thin Coatings

Eddy current testing (ECT) technology works on the principle of magnetic coupling of a probe sensor (coil) close to a test specimen (conductive material, ferromagnetic or non-ferromagnetic), generating eddy currents inside the test specimen, and displaying signals on the instrument’s impedance plane. With eddy current technology, you can detect defects through thin coatings (such as paint), as long as the distance from the probe to the metal is kept reasonably low—typically in the order of 0.5 mm to 2.0 mm.

As eddy current array and ECT technology share the same basic principles (and physics), it can also perform inspections through paint while offering all advantages of ECA, including large coverage, fast scanning, high probability of detection and color imaging.

Specification:

| 321 mm x 209 mm x 125 mm (12.6 in. x 8.2 in. x 5.0 in.) | |

| 4.6 kg (10.1 lb), including module and one battery | |

| 21 cm (8.4 in.) TFT LCD Display, 800 pixels x 600 pixels, 16 million colors | |

| Smart Li-ion batteries (up to 2), and DC-in voltage 15 V to 18 V (min. 50 W) | |

| Minimum 6 hours with two batteries; minimum 3 hours per battery under normal operating conditions | |

| CompactFlash card, most standard USB storage devices, or through fast Ethernet, internal 32-MB DiskOnChip | |

| 3 USB ports, Video output Video out (SVGA), Ethernet 10/100 Mbps, 2-axis encoders, 4 digital inputs (TTL). | |

| 0 °C to 40 °C; 0 °C to 35 ºC with 32:128 PA (32 ºF to 104 ºF; 32 ºF to 95 ºF with 32:128 PA) | |

| –20 °C to 70 °C (–4 ºF to 158 ºF) Relative humidity 0 % to 95 % noncondensing. No air intake; splashproof design. | |

| Supports conventional eddy current and bond testing C-scan (adaptors not included) | |

| Supports eddy current arrays, conventional eddy current, and bond testing C-scan (adaptors not included) | |

| BNC Absolute Probe (ECT), 4-channel Universal Fischer 19 pins (ECT and BT), and OmniScan connector for ECA probes | |

| 1 to 4 (ECT); 32 (ECA), expandable up to 64 with external multiplexer; 1 (BT) with adaptor | |

| Absolute, differential, bridge, reflection (driver-pickup) for both ECT and ECA probes. Support select BondMaster pitch-catch probes through use of an adaptor (scanner also required). | |

| Automatic probe recognition and setup for ECA and BT probes. | |

| 2 typical for most ECA and ECT setups or up to 8 on custom ECT applications or Bond Testing C-scan | |

| 20 Hz to 6 MHz | |

| 12 Vp-p into 10 Ω | |

| ECT and ECA: 34 dB to 74 dB. BT: 28 dB to 68 dB. Additional adjustable software gain of 0 dB to 30 dB. | |

| 0° to 360° with increments of 0.1° | |

| 1 Hz to 15 kHz, variable depending on configurations. | |

| 16 bits | |

| FIR low-pass, FIR high-pass, FIR band-pass, FIR band-stop (adjustable cutoff frequency), median filter (variable from 2 points to 200 points), mean filter (variable from 2 points to 200 points) | |

| True automatic mixing, sensitivity normalization and encoder calibration | |

| Time-based, one line scan or raster scan (2 axis) | |

| 3 alarms, each configurable as Pie, Box, Ring/Circle. Alarm output as Visual, TTL and Sound. | |

| Yes – one channel only. |