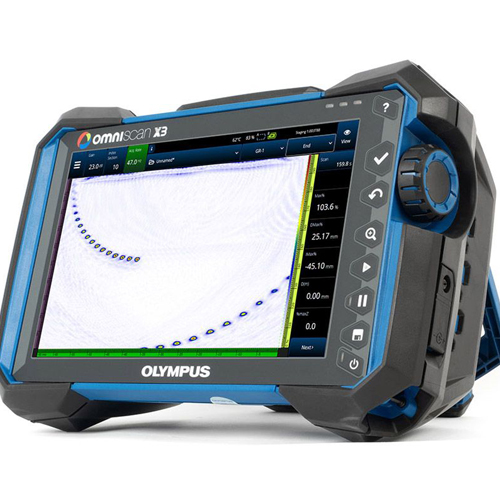

Olympus OmniScan SX PA 16:64PR Phased Array Flaw Detector

The OmniScan SX comes in two models: the SX PA and SX UT. The SX PA is a 16:64PR phased array unit, which, like the UT-only SX UT, is equipped with a conventional UT channel for pulse-echo, pitch-catch or TOFD inspection. Compared to the OmniScan MX2, the SX is 33% lighter and 50% smaller, offering an unprecedented level of portability for an OmniScan.

The OmniScan SX touch screen offers a full-screen mode option that maximizes visibility, essentially converting many menu functions into easy touch-screen operations. The intuitive interface provides smooth menu selection, zooming, gate adjustments, cursor movements, and text and value input. These, along with other premium integrated features, including easy-to-follow setup and calibration Wizards, a rapid refresh rate for both the S-scan and A-scan displays, and a fast pulse repetition frequency (PRF), make the OmniScan SX a highly efficient inspection tool.

Olympus OmniScan SX is proud to introduce the OmniScan® SX, a flaw detector that benefits from more than 20 years of phased array experience and shares the OmniScan DNA. For improved ease of use, the OmniScan SX features a new streamlined software interface displayed on an 8.4 in. (21.3 cm) touch screen.

Olympus OmniScan SX A single-group and non-modular instrument, the OmniScan SX is easy to operate and cost-effective for less demanding applications. The OmniScan SX comes in two models: the SX PA and SX UT. The SX PA is a 16:64PR phased array unit, which, like the UT-only SX UT, is equipped with a conventional UT channel for pulse-echo, pitch-catch or TOFD inspection. Compared to the OmniScan MX2, the SX is 33% lighter and 50% smaller, offering an unprecedented level of portability for an OmniScan.

What’s include the box;

- Olympus OmniScan SX 16:64 PA Flaw Detector

- Battery Pack

- AC Adapter/Charger

- Power Cord

- User Manual On Cd-ROM

- Carrying Case (G)

Setup

Inspection setup can be performed in NDT SetupBuilder, and imported directly, via SD card or USB key, to the OmniScan SX. Then, only a few basic operations are required in the instrument, such as setting the gate and range, before acquisition can begin. It is also very easy to create a setup right in the OmniScan SX, thanks to the following features:

- Automatic probe recognition.

- One-step, preconfigured application Wizard.

- Weld Overlay and RayTracing simulation

Calibration

To achieve a code-compliant inspection, the Calibration Wizard ensures that every focal law in every group is the direct equivalent of a single-channel conventional flaw detector. The user is guided step-by-step through the required calibrations, including Velocity, Wedge Delay, Sensitivity, TCG, DAC, AWS, and encoder calibrations. Now, TOFD PCS calibration and lateral wave straightening can be performed automatically.

Acquisition

The OmniScan SX enables easy configuration of inspection parameters for either manual, one-line, or raster encoded scans. The acquisition is displayed in real time through user-selectable views and offers the ability to store data on a hot-swappable SD card or USB 2.0 device.

- Intelligent layouts

- Full-screen mode for better visualization of defects

- Synchronization and measurements can be processed using different gate combinations

Data Analysis and Reporting

- Data, reference, and measurement cursors for defect sizing

- Extensive readings database and predefined lists for trigonometry, flaw statistics on axes, volumetric position information, code-based acceptance criteria, corrosion mapping statistics, and more

- Views are linked for interactive analysis and automatically updated when performing off-line gate repositioning

- Optimized preconfigured layouts for quick and simple length, depth, and height sizing of flaws

Whether you prefer performing data analysis on a computer or simply wish to maximize the time your OmniScan is at work in the field, OmniPC or TomoView are the perfect software companions for your OmniScan.

Affordable and Portable Go a Long Way….

The Omniscan® SX provides Olympus with a new and versatile tool to add to its arsenal of innovative and creative complete market solutions aimed at simplifying your workflow and improving overall productivity.

Phased Array Weld Inspection

The OmniScan PA is at the heart of the manual and semiautomated phased array weld inspection solutions developed by Olympus for the oil and gas industry. These systems can be used for inspection in compliance with ASME, API, and other code criteria, while offering highspeed detection capabilities, and facilitating indication interpretation.

Corrosion Mapping and Composite Inspection

Zero-degree inspection just became even more accessible with the arrival of the OmniScan SX. For corrosion or composite inspection, Olympus offers field-proven solutions for detection of anomalies or wall loss.

TOFD Weld Inspection

TOFD is an easy and efficient approach for primary detection of weld defects. It is quick, cost-effective and capable of sizing defects present in the volume of the weld, a problematic area for manufacturing defects.

Component Inspection

Using ultrasonic techniques, inspection of components can detect cracks, wall loss, and other damage. With the capacity for both angle and linear zero-degree beams, the OmniScan SX is a very cost-efficient solution for this type of single-group inspection.

Features:

- Cost-efficient, single-group

- Two-axis encoding and data archiving capacity

- Conventional UT, TOFD, and 16:64PR PA capabilities

- 8.4 in. (21.3 cm) touch screen with OmniScan interface

- Compact, lightweight design

Specifications:

| Housing | |

| Overall dimensions (W x H x D) | 267 mm × 208 mm × 94 mm (10.5 in. × 8.2 in. × 3.7 in.) |

| Weight | 3.4 kg (7.5 lb) with battery |

| Data Storage | |

| Storage devices | SDHC card or most standard USB storage devices |

| Data file size | 300 MB |

| I/O Lines | |

| Encoder | 2-axis encoder line (quadrature, up, down, or clock/ direction) |

| Digital input | 4 digital TTL inputs, 5 V |

| Digital output | 3 digital outputs TTL, 5 V, 15 mA maximum per output |

| Acquisition on/off switch | Yes, through configuration of a digital input |

| Power output line | 5 V, 500 mA power output line (short-circuit protected) |

| Pace input | 5 V TTL pace input |

| Display | |

| Display size | 21.3 cm (8.4 in.) (diagonal) |

| Resolution | 800 pixels x 600 pixels |

| Brightness | 600 cd/m2 |

| Viewing angles | Horizontal: –80° to 80° Vertical: –60° to 80° |

| Number of colors | 16 million |

| Type | TFT LCD |

| Power Supply | |

| Battery type | Smart Li-ion battery |

| Number of batteries | 1 |

| Battery life | Minimum 6 hours under normal operating conditions |

| Environmental Specifications | |

| Operating temperature range | -10 °C to 45 °C (14 ºF to 113 ºF) |

| Storage temperature range | –20 °C to 60 °C (–4 ºF to 140 ºF) with battery –20 °C to 70 °C (–4 ºF to 158 ºF) without battery |

| Relative humidity | Max. 70% RH at 45°C noncondensing |

| Ingress protection rating | Designed to meet requirements of IP66 |

| Shockproof rating | Drop-tested according to MIL-STD-810G 516.6 |

| Ultrasound Specifications | |

| Connectors | 1 Phased Array connector: Olympus PA connector 2 UT connectors: LEMO 00 |

| Number of focal laws | 256 |

| Probe recognition | Automatic probe recognition |

| Pulser/Receiver | |

| Aperture | 16 elements |

| Number of elements | 64 elements |

| Pulser | |

| Voltage | 40 V, 80 V, and 115 V |

| Pulse width | Adjustable from 30 ns to 500 ns; resolution of 2.5 ns |

| Pulse shape | Negative square wave |

| Output impedance | 35 Ω (pulse-echo mode); 30 Ω (pitch- catch mode) |

| Receiver | |

| Gain | 0 dB to 80 dB, maximum input signal 550 mVp-p (full-screen height) |

| Input impedance | 60 Ω (pulse-echo mode); 150 Ω (pitch- catch mode) |

| System bandwidth | 0.6 MHz to 18 MHz (–3 dB) |

| Beamforming | |

| Scan type | Sectorial or linear |

| Group quantity | 1 |

| Data Acquisition | |

| Digitizing frequency | 400 MHz (12 bits) after interpolation per 5/4 |

| Maximum pulsing rate | Up to 6 kHz (C-scan) |

| Data Processing | |

| Number of data points | Up to 8,192 |

| Real-time averaging | PA: 2, 4, 8, 16 |

| Rectifier | RF, full wave, half wave , half wave – |

| Filtering | 3 low-pass, 3 band-pass, and 5 high-pass filters |

| Video filtering | Smoothing (adjusted to probe frequency range) |

| Data Visualization | |

| A-scan refresh rate | A-scan: 60 Hz; S-scan: 60 Hz |

| Data Synchronization | |

| On internal clock | 1 Hz to 6 kHz |

| On encoder | On 2 axes: from 1 to 65,536 steps |

| Programmable Time-Corrected Gain (TCG) | |

| Number of points | 16: One TCG (time-corrected gain) curve per focal law |

| Maximum slope | 40 dB/10 ns |

| Alarms | |

| Number of alarms | 3 |

| Conditions | Any logical combination of gates |